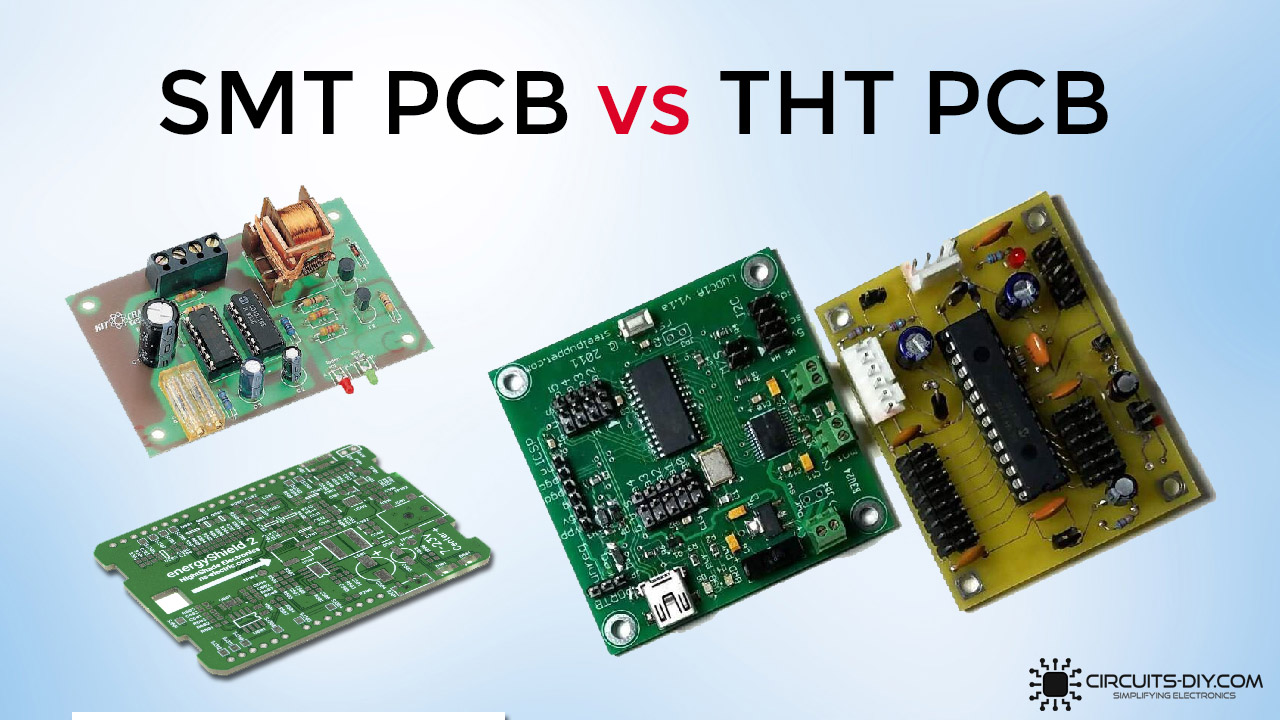

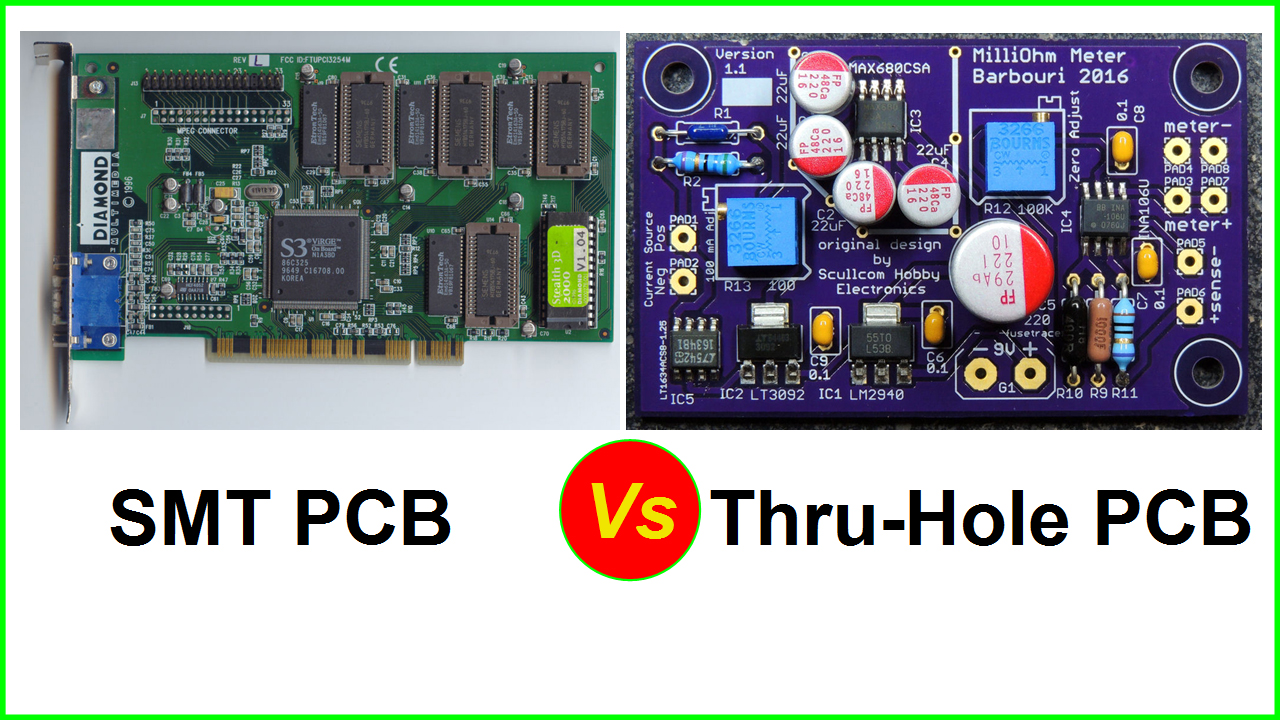

in recent years, the field of semiconductor design and packaging has evolved & with a continuous decrease in the technology size of new semiconductor parts; the industry is demanding greater functionality, smaller size, and added utility. Currently, the PCB design industry is dominated by two PCB mounting technologies. THT (through hole technology) and SMT (surface mount technology). In today’s article, we are going to look into the advantages and disadvantages of THT vs SMT PCB; what both technologies have to offer in terms of design reliability and robustness.

THT VS SMT PCB Technology

Through Hole Technology (THT)

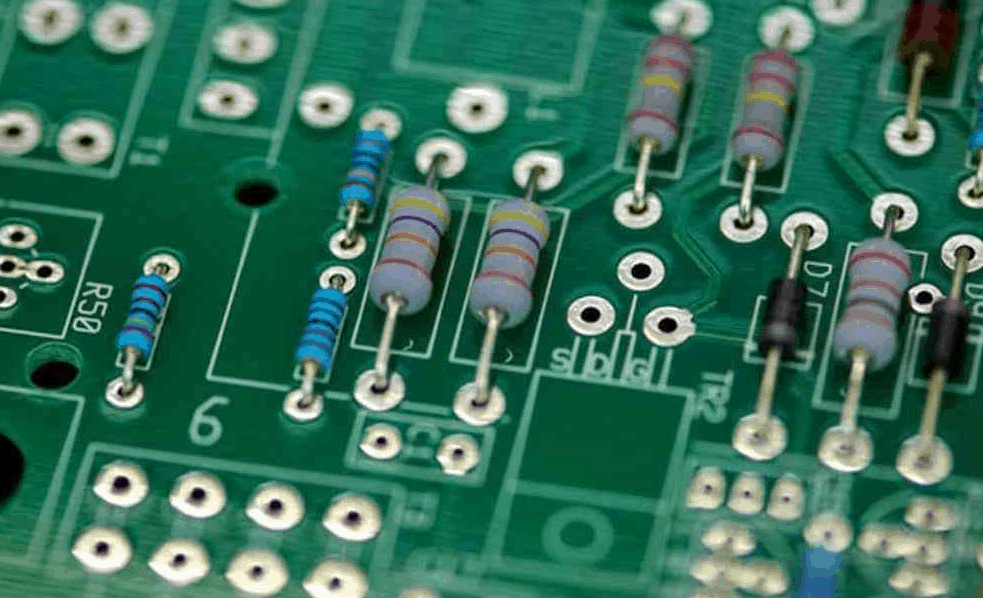

THT refers to through hole technology, meaning that the component leads will be inserted into preset holes on a PCB card and then soldered on using wave soldering. They are generally used for robust PCB products that require stronger connections between PCB layers. This technology has its application in military and aerospace products that may experience extreme accelerations, collisions, or high temperatures. THT is also useful in test and prototyping applications that sometimes require manual adjustments and replacements.

Types of THT Components

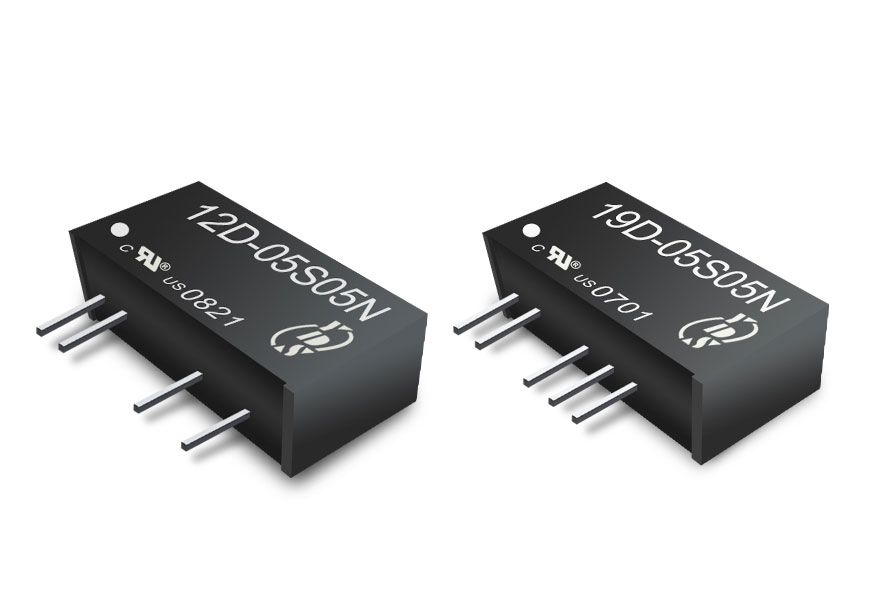

1) Single ended THT components / Single in Line THT package (SIP)

2) Double ended THT components / Dual in Line THT package (DIP)

3) THT Pin grid array

Advantages of THT Technology

- THT assemblies are highly resistant to wear and tear; as a result of the large solder joints that extend throughout the width of the board itself.

- This makes THT PCB boards the first level of priority for military and aerospace applications, where the device may suffer from mechanical stress and vibrations.

- THT components are also easy to swap out, making them perfect for prototypes and testing.

- THT offers stronger mechanical bonds in contrast to SMTs; where, the component parts are in simple contact with the board. This makes THT components ideal for high electrical/mechanical stress environments such as connectors or transformers.

Disadvantages of THT Technology

- THT boards require drilling holes; so, that the components can fit into them. This increases their production cost and also increases the production time for each individual board.

- THT also restricts the available routing clearance on any multi layer board. This is because the drill holes must pass through every PCB layer.

- The soldering of THT components on an industrial scale is usually done by using the wave soldering process, which is inherently less reliable than the reflow soldering process.

Surface Mount Technology (SMT)

Surface Mount Technology is a method for constructing electronic circuits in which SMC components mount directly onto the surface of the Printed circuit board. Electronic devices made for this purpose are called surface mount devices or SMDs. In an SMT PCBA, the solder joint forms the physical & mechanical connections. Also, the bonding of the solder joint is to the surface of a conductive landing pattern.

Types of SMTs

Incorporating with PCBs & active/passive SMCs. SMT PCBs are of 3 major types:

- Type I — Full SMT board with parts on one or both sides of the PCB board.

- Type II — Surface mount Chip components are on the secondary side of the PCB board. Active SMCs or DIPs are on the primary side of the board.

- Type III — This type of SMT PCBA uses passive chip SMCs on the secondary side of the PCB board. But the primary side of the board only uses DIP parts.

Advantages of SMT Technology

- Since the components have no leads or short leads. The parameter distribution of the circuits is naturally lower and the RF interference is also low.

- Due to enhanced production equipment & the lower packaging material consumption. The packaging cost of most SMT components has been lower than that of THT components with the same type and function

- Due to the standardization, serialization, and consistency of welding conditions of SMT parts, component failure by the welding process will be low and the reliability will improve.

Disadvantages of SMT Technology

- High wattage parts do not pair well with SMT parts as it will lead to excess thermal dissipation which may damage the SMDs on the PCB board.

- Since SMT components are of extremely small size, their repair work can be a lot more complex than THT components.

- Another disadvantage of using SMT components in PCBA is that the SMT PCB cards cannot be a subject of roughhousing or rough handling.

In conclusion, the above guide gives us a look into the advantages and disadvantages of THT vs SMT PCB.