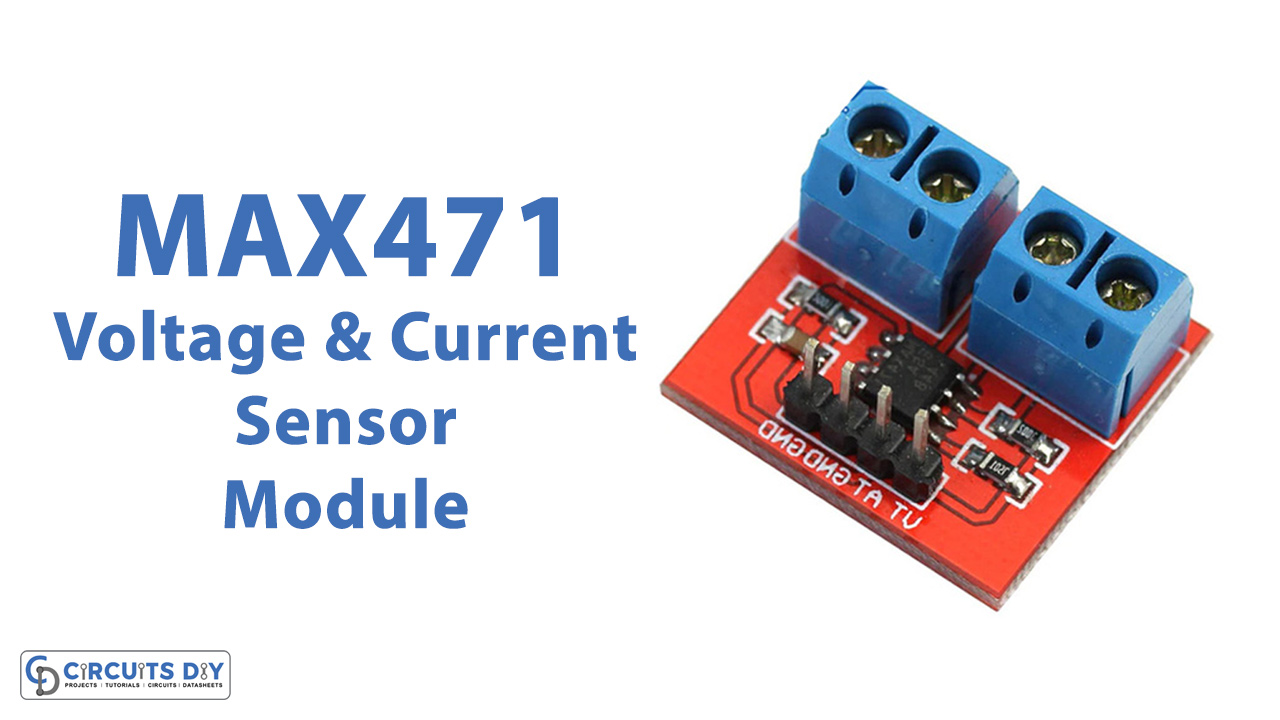

An Overview MAX471

Hardware Overview

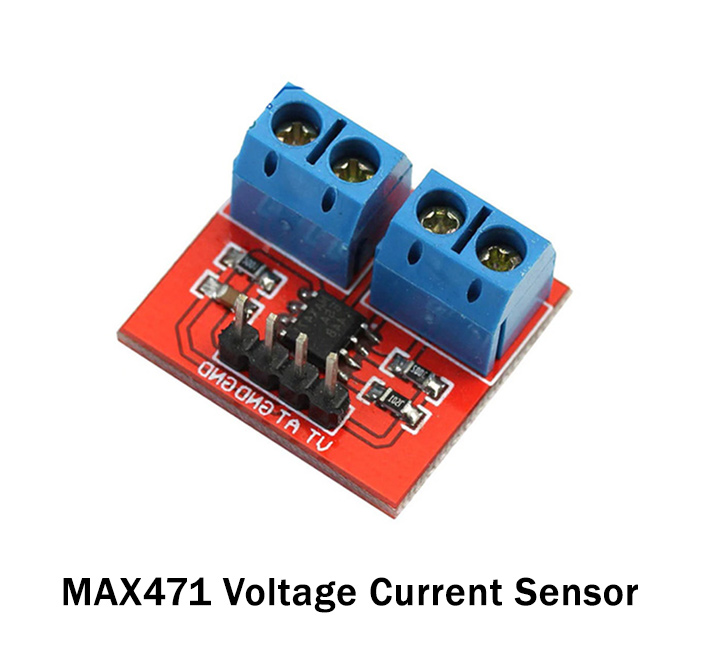

MAX471 Sensor contains an IC that can take an input voltage from the range of 3V to 36V. Inside the IC, there is a sensing resistor, and it’s across these there are two Blue color terminals. It also connected these terminals with the RS- and RS+ pins. The four pins are there to connect with the microcontroller.

Interfacing with Microcontroller

There are five pins of activity on this device sensor. To interface the sensor with any microcontroller, you need to connect RS+ to the positive pole of your supply source while RS- to the high side of your load, connect ground to the ground of the system. Now, connect the remaining OUT (an analog output) to your microcontroller.

Features and Specifications of MAX471 Sensor

Features

- Monitors Both Charge and Discharge

- Complete High-Side Current Sensing

- Precision Internal Sense Resistor

- Monitors Both Charge and Discharge

- 3A Sense Capability with Internal Sense Resistor (MAX471)

- Higher Current-Sense Capability with External Sense Resistor (MAX472)

- 8-Pin DIP/SO Packages

- Vast range of applications

- Energy Management

Specifications

- Current sens max: +/- 3A

- 100µA Max Supply Current

- 18µA Max Shutdown Mode

- Current sens voltage: 3 to 36V

- Sensor output: 1V / Amp

- Dimensions: 20mm x 19.5mm

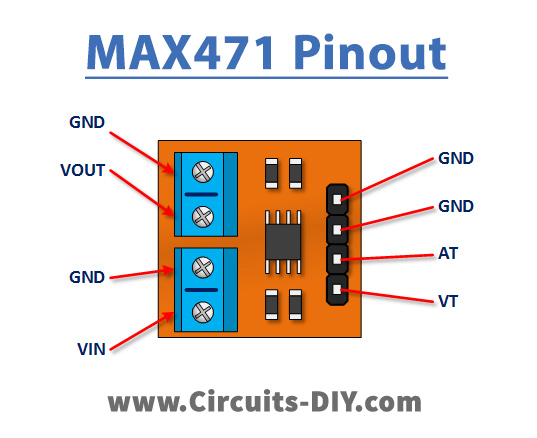

Pinouts of MAX471

| PIn Name | Description |

| RS+ | Alternative load positive supply (3 to 36V) |

| GND | .Connect to loads 0V/GND supply |

| OUT | Current sensor output (1V / Amp, 3V max) |

| SIGN | Current flow direction. An open-collector |

| GND | Alternative GND (Connect to loads 0V/GND supply) |

| RS- | Alternative load/charger connection. |

Applications of MAX471 Sensor

Smart Battery Packs

A smart battery pack provides information that can manage the charging of the device. In the battery packs, the current sensor can measure current flow into and out of the battery.

Energy Management Systems

Connection current sensors with energy monitoring software to monitor each machine’s energy use may help to give accurate, real-time energy consumption data and present usage. From which, it could make informed decisions on where energy can be stored.