Introduction

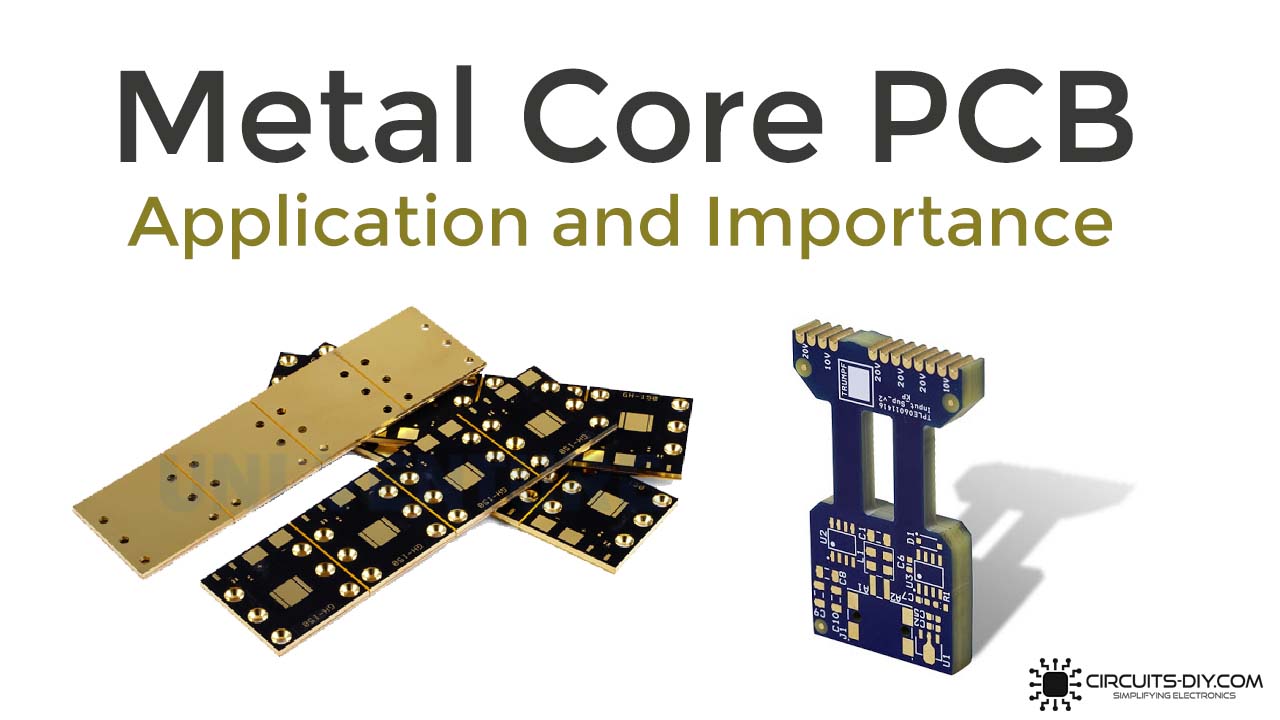

In printed circuit boards, the base of the board is the primary part of the circuit. And, we have studied the substrate used as the base in PCB. But, that substrate is not thermally efficient. To meet the needs of high thermal products, here comes the metal core PCB. MCPCB is the abbreviation of the metal-core printed circuit board. It is also popular as the thermal PCB. It contains the metal material as its base. This material is usually copper or aluminum covers one side of the PCB

The main purpose of the metal core is to change the direction of heat away from the printed circuit board. Hence, it transfers the heat eight to nine times faster than the simple PCB. It also keeps the components cool. As a result, efficiency and performance of for it increases. It prevents the circuit from damages.

Thickness and Material for Metal Core

- The thickness of the material uses in metal core PCB is normally 30 mil to 125il. But more than thicker or thinner from this range can be practical for desired circuits.

- Usually, aluminum is widely used for this purpose. Copper or heavy copper is also used sometimes. Other materials like steel and brass have been used too. However, they are not recommended or preferable.

Advantages of Metal Core

Metal core PCB has a wide variety of applications. These applications exist because of the advantages that have been provided by PCB by this metal core. Discussing some of the benefits below

- The thermal conductivity or proficiency is very high as compared to the other FR4 PCB. Because the material of FR4 PC is very awful in conducting heat. On the other hand, this metal for PCB has good conductivity which helps to protect the layer and the components.

- The metal core has better dimensional stability as compared to the FR4. When it gets heat about 30 to 150 degrees, it changes its size from at least 2.5 to 3 percent.

- Since it has great thermal conductivity. That’s why it causes less distortion in the circuit. This property is considered good for high switching power applications.

- Hence it retains good thermal expansion. This means it overcomes the issues related to thermal expansion and contraction. Therefore, the device that uses a metal core has a high durability rate.

- It diminishes the vias. Because the metal layer itself is thermally conductive. It only requires drilling of a few large mounting holes

Application and Uses

The metal core has an enormous range of applications and use. Some are:

- Automotive LED applications

- Photovoltaic application

- In power supplies

- Telecommunication.Voltage Regulator

- Industries

- Hybrid motor control, etc

- Solid State Relays

Because of these applications, metalcore has created a considerable place in the PCB market. It has solved the problem of dissipating heat. Hence, used in so many applications of circuits.

Future of Metal Core

The metal core PCBs have expanded through extensive research and analysis. Since it uses metal, therefore the primary target is the metal core PCB countries. Its vast application has increased the number of manufacturers that are running in the global metalcore market.