Liquid level indication systems are cheap, durable & easy to design. They are essential in many facets of today’s industry, whether it be the lab of a small-scale chemist or reservoirs/water boilers of an industrial-scale operation. So, in today’s project, we are going to build a Simple Water Level Indicator using a configuration of BC337 NPN Transistors.

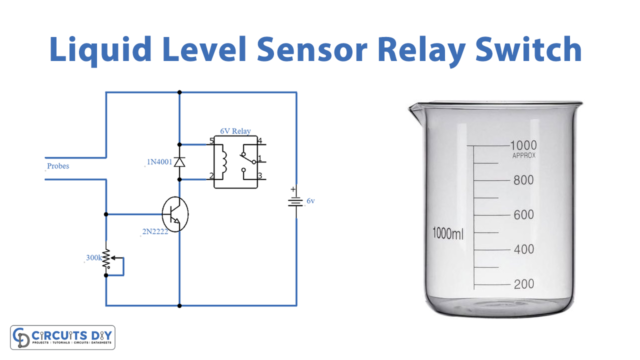

A Water level indicator is a simple electronic circuit that can indicate the level of any conductive liquid contained in a vessel such as a reservoir, overhead/underhead tank, or container. There are a number of electronic configurations available for achieving this function. here, we will be following a simple transistor switching technique.

PCBWay commits to meeting the needs of its customers from different industries in terms of quality, delivery, cost-effectiveness, and any other demanding requests. As one of the most experienced PCB manufacturers in China. They pride themselves to be your best business partners as well as good friends in every aspect of your PCB needs.

Hardware Components

The following components are required to make Water Level Indicator Circuit

| S.no | Component | Value | Qty |

|---|---|---|---|

| 1. | Water Level Indicator PCB | PCBWAY | 1 |

| 2. | Transistor | BC337 | 5 |

| 3. | Buzzer | 5V | 1 |

| 4. | Resistor | 1K | 6 |

| 5. | LED | 5mm, Red/Green | 6 |

| 6. | Soldering Iron | 45W – 65W | 1 |

| 7. | Soldering Wire with Flux | – | 1 |

| 8. | DC Battery | 9V | 1 |

| 9. | Battery Clip | – | 1 |

| 10. | Jumper Wires | – | As per need |

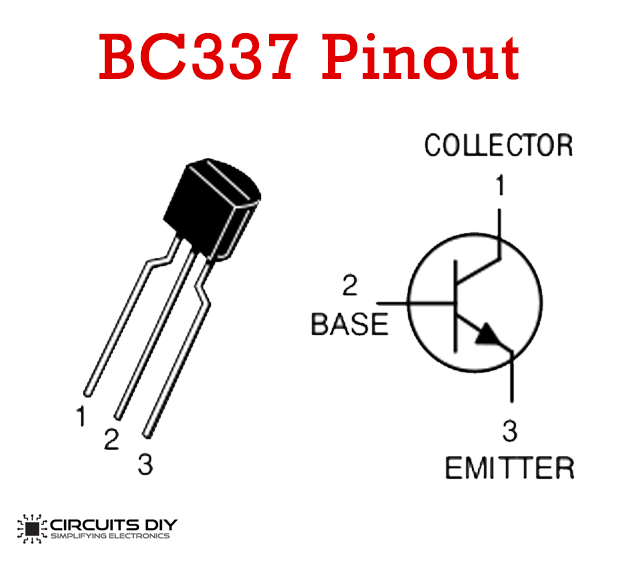

BC337 Pinout

For a detailed description of pinout, dimension features, and specifications download the datasheet of BC337

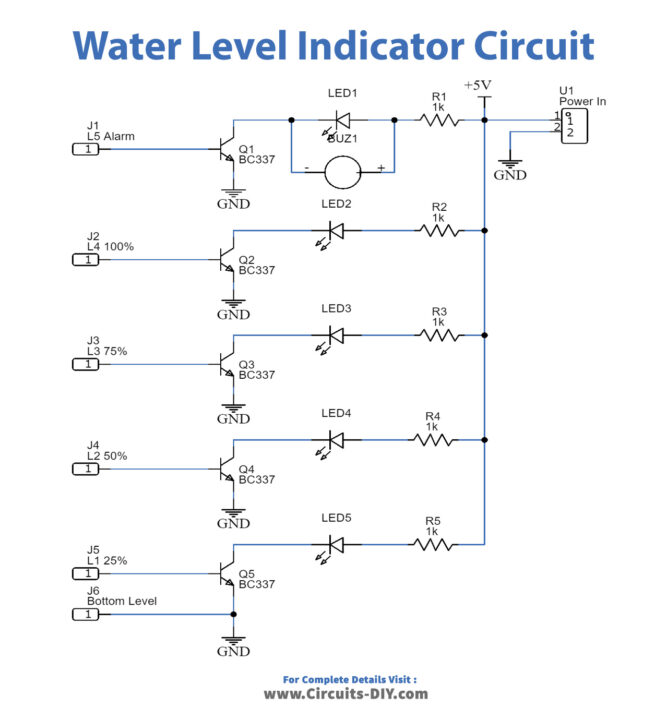

Water Level Indicator Circuit

Working Explanation

The working of this circuit is pretty simple, six terminals fashioned from the exposed end of wires are attached at appropriate heights in the vessel or reservoir (from the bottom level to the Overflow alarm). On filling the vessel with water via a pump, each LED glows with respect to the terminal in contact with the water, which sends a control signal to the base of each BC337. The resultant collector output triggers the LED to glow indicating the current level of the water in the vessel.

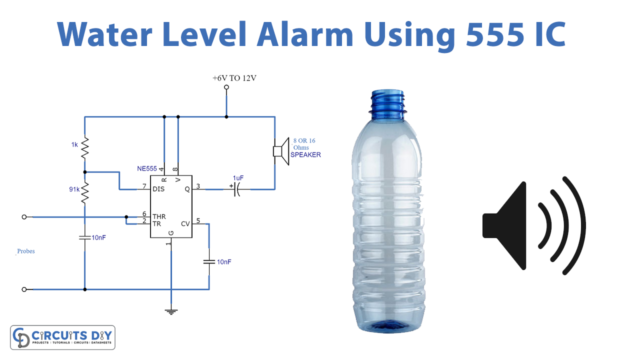

When the water reaches the top of the container & makes contact with the alarm terminal, it triggers the overflow indicator LED & the buzzer goes off.

Applications

- An important part of wide-scale industrial processes such as cooling tower water level control, life station switches, tsunami warning systems, irrigation control, fuel tank level gauging & sump pumps