Introduction

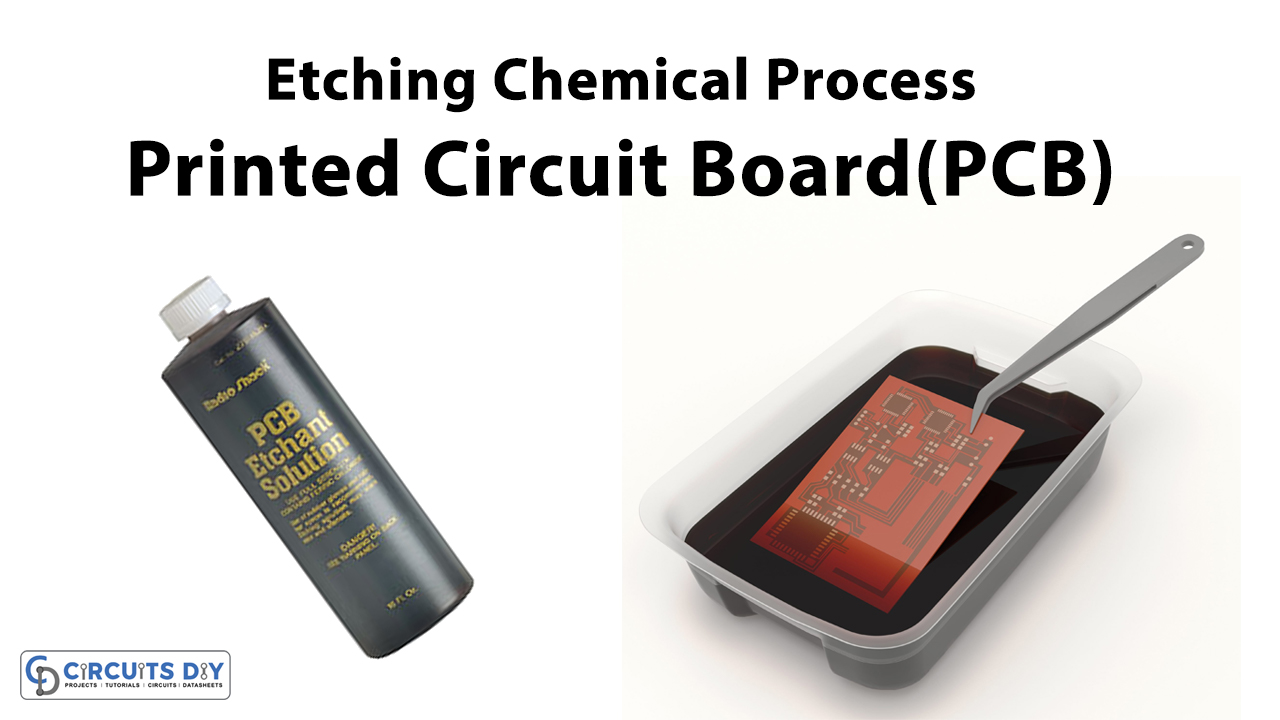

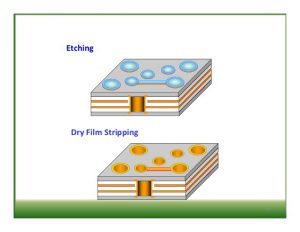

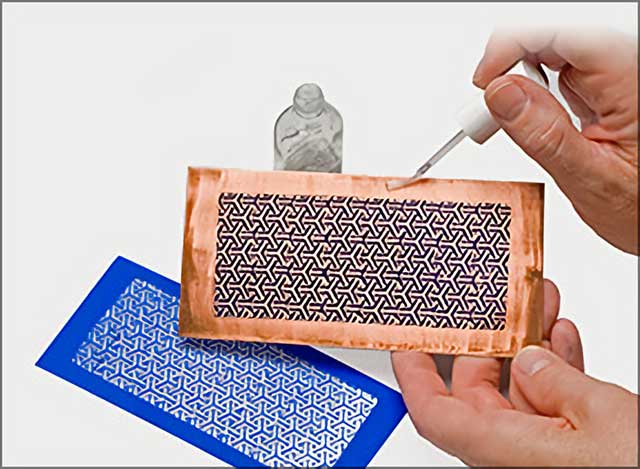

Printed circuit boards that are part of every other electronic device require the whole manufacturing and fabrication process. Electronic devices seem easy to make but they require a great amount of effort and time. And, not just the time, it also needs money in its fabrication process. Because the process needs chemicals for the fabrication. Hence Printed circuit boards use solvents like cupric chloride ammoniacal etchant, sulphuric acid, etc for their etching process of manufacturing. Therefore, in this article, we will briefly discuss those basic chemicals used in the etching process of PCB.

Etchant Liquids

The waste from the PCB-making process contains used etchant and waste rinse water that comprises chromium, iron, ammonia, copper, and acids. Mostly, materials that make the waste streams consist of suspended solids, metals, chelating agents, phosphorus, fluoride, cyanide, etc. Manufacturers use various methods of processing to reuse the water. Those processes include the addition of other chemicals that react with soluble pollutants, filtration and removal of sludge, reverse osmosis, ion exchange, membrane filtration, and different types of rinsing techniques.

Types of Etchants

Fundamentally there are two main types of etchants ammonical etchant and cupric chloride. But, before these two chemicals, manufacturers used ferric chloride as an etchant. Therefore we will discuss all three and will compare them all.

- Ferric chloride: Ferric chloride is highly corrosive and can cause moderate problems while disposal and neutralizing. Moreover, the chemical is not toxic to use.

- Ammoniacal etchant: Ammoniacal etchant is highly corrosive because of the presence of ammonia in them. And, can cause moderate problems while disposal and neutralizing. Hence, this chemical is moderately toxic to use.

- Cupric Chloride: Cupric Chloride is also highly corrosive. However, it can cause only a few problems while disposal and neutralizing. Also, the chemical is not toxic to use.

Regeneration of Cupric Chloride

Manufacturers can regenerate waste cupric chloride. Because regeneration enables chemicals to recover. The regeneration of cupric chloride eliminates pollution from the material. Hence, preferable to use. However, it needs the addition of at least one more chemical. These chemicals can be hydrochloric acid, hydrogen peroxide, chlorine gas, etc. But, some of these chemicals like chlorine gas require specialized methods to prevent their release into the environment, Also, some of the chemicals are easier to use and therefore, can be used as an alternative to chlorine gas. For example, sodium chlorate can be used instead of chlorine gas.

Conclusion

The chemicals used in the manufacturing and etching process of PCB play an important role to give life to the printed circuit board. Also, it takes a crucial part to decide the lifespan of the PCB. It can affect the durability rate and the reliability of the Board. Moreover, the most commonly used chemical is ferric chloride. But some other chemicals can also be used in the etching process. One of them is cupric chloride. Hence, the regeneration of the cupric chloride may help to prevent pollution from the printed circuit board. Remember while using these chemicals in the etching process one must have taken careful measures.